400-9611-109

Product Maintenance Plan

Source: 思贝乐Date: 2025-10-1609:32:54 Reading volume:

I. Core Philosophy

“Full-Lifecycle Energy Efficiency Stewardship”

Centered on preventive maintenance, we safeguard equipment energy performance through periodic servicing, extend service life, and reduce customers’ total cost of ownership.

II. Tiered Maintenance Program

Maintenance Level | Service Interval | Key Tasks |

Level A Maintenance | 500–1000 operating hours / every 3 months | Appearance inspection, lubrication system upkeep, vibration & noise check, energy data logging |

Level B Maintenance | 3000–4000 operating hours / annually | Seal replacement, bearing calibration, impeller cleaning, control system diagnostics |

Level C Maintenance | 8000–10000 operating hours / every 2–3 years | Core component teardown & inspection (rotor/gearbox), dynamic balance correction, efficiency optimization tuning |

Level D Maintenance | Mid-life stage (3–5 years) | Material flaw detection (NDT), insulation aging test, energy-control system upgrade |

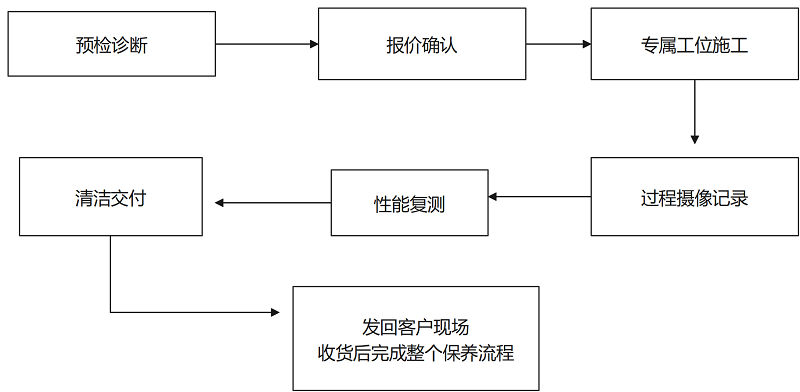

III. Standardized Service Workflow

Customer Appointment System

1. Book maintenance slots via online platform or phone.

2. Automatic retrieval of equipment files (model / maintenance history).

Six-Step Work Order Process

Dual-Report Mechanism

1. Equipment Health Report: Energy-efficiency curve comparison, key component wear rating.

2. Energy-Savings Report: Pre-/post-maintenance energy consumption comparison with annual electricity-cost savings projection.

IV. Featured Service Modules

1. Maintenance Package Plans

Package Type | Contents | Customer Benefits |

Basic Protection Package | 2× Level A + 1× Level B + emergency rescue | Labor fee waived; 10% off spare parts |

Energy-Efficiency Value Package | Full-cycle A+B+C maintenance + annual energy audit | Free control system upgrade |

Enterprise VIP Contract | Resident on-site engineer inspections + spare-parts stock | Downtime compensation insurance |

2. Digital Steward System

2.1 IoT equipment access: real-time monitoring of vibration / temperature / current

2.2 Automated early warning: maintenance reminders pushed 30 days in advance

2.3 Electronic archive: scan code to view full lifecycle data

3. Energy Performance Assurance

3.1 Sign the “Energy Efficiency Maintenance Agreement”: free rework if post-maintenance energy use fails to meet targets

3.2 Provide energy-savings certification report (compliant with ISO 50001)

V. Customer Value Enhancement

1. Loyalty Program

Points redemption: exchange maintenance points for filters/seals

Referral rewards: maintenance credit after successful contract signing

2. Emergency Response Mechanism

2-hour fault response

Backup unit rental (for critical production lines)

3. Training Services

Free online operation training

VI. Execution Assurance System

1. Spare-Parts Supply Chain Management

OEM anti-counterfeit traceability (QR verification)

2. Service Quality Monitoring

Customer follow-up within 72 hours after maintenance

Quarterly customer satisfaction survey

Return to list

Return to list